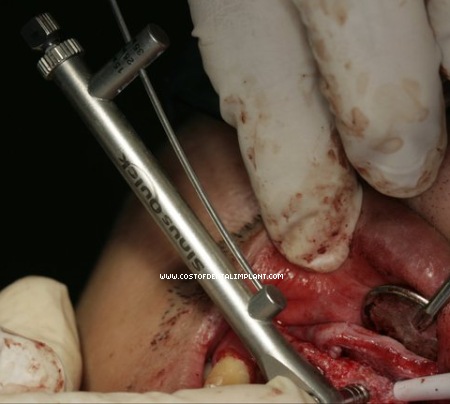

For final tightening of the dental implant, torque ratchet is used. It is also used to measure the exact torque of the dental implant. Over threading is also prevented by using the torque ratchet. Over threading could strip all threads in bone.

Neobiotech torque ratchet is used to measure the exact torque of the dental implant. Photo credit: Oris Neobiotech